High reputation Mica Flake Rock - Dry ground mica – Huajing

High reputation Mica Flake Rock - Dry ground mica – Huajing Detail:

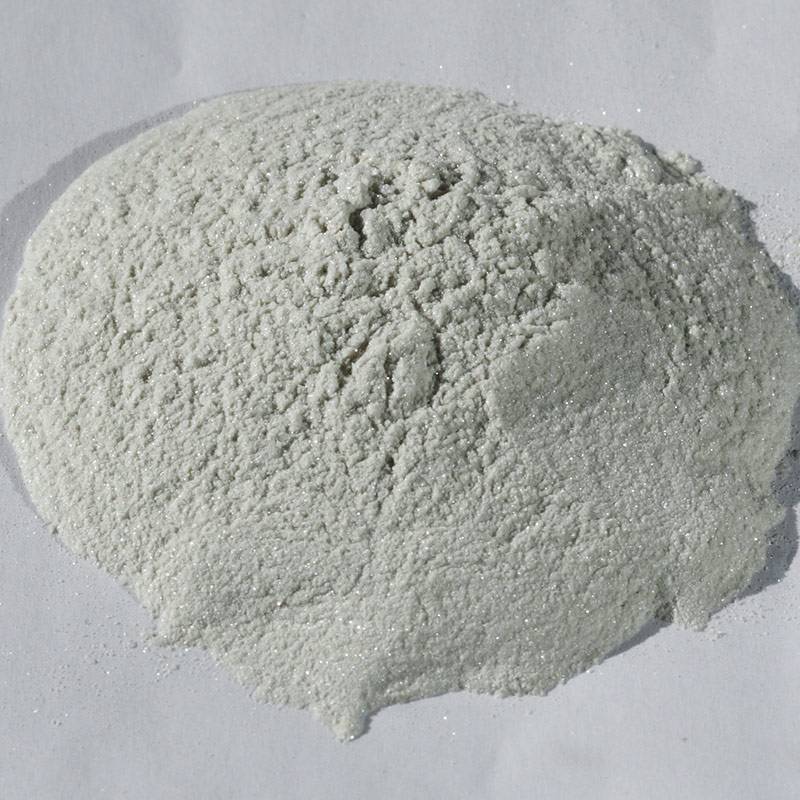

Plastic Grade Mica Powder

| Sice | Color | Whiteness (L.a.b.) | Particle Size (μm) | Purity(%) | Magnetic Material (ppm) | Moisture(%) | LOI(650℃) | Ph | Osbestos | Heavy Metal Component | Bulk denisty (g/cm3) |

| Dry Mica(Filler) | |||||||||||

| D-60 | Silver White | 80~83 | 170 | >98 | <500 | <0.5 | 4.5~5.5 | 7.8 | NO | <10ppm | 0.28 |

| D-100 | Silver White | 82~86 | 120 | >98 | <500 | <0.5 | 4.5~5.5 | 7.8 | NO | <10ppm | 0.26 |

| D-200 | Silver White | 82~86 | 68 | >98 | <300 | <0.5 | 4.5~5.5 | 7.8 | NO | <10ppm | 0.24 |

| D-300 | Silver White | 83~86 | 50 | >98 | <500 | <0.5 | 4.5~5.5 | 7.8 | NO | <10ppm | 0.23 |

| D-400 | Silver White | 84~88 | 45 | >98 | <500 | <0.5 | 4.5~5.5 | 7.8 | NO | <10ppm | 0.22 |

PP’S Different Effections After Adding Mica, Talc, Caco3, Glass Fiber

| Property | No fill | PP+40% | PP+40% | PP+30% | PP+40% | PP+40% |

| PP | talc(commodity) | CaCO3(commodity) | Glass fiber | Natural mica mineral | Finished Mica | |

| (commodity) | ||||||

| Tensile strength(Mpa) | 4930 | 4270 | 2770 | 6340 | 4050 | 6190 |

| Bending strength (Mpa) | 4450 | 6420 | 4720 | 10060 | 6450 | 9320 |

| Bending modulu /(Gpa) | 0.193 | 0.676 | 0.421 | 0.933 | 0.934 | 1.04 |

| Notched impact strength (KJ/m2) | 0.45 | 0.45 | 0.75 | 0.79 | 0.7 | 0.65 |

| 136 | 162 | 183 | 257 | 190 | 226 | |

| Hot deformation temperaturer℃ | ||||||

| Hardness(D hardness tester) | 68 | 72 | 68 | 69 | 68 | 73 |

| Shrinkage ratio (lengthways)% | 2 | 1.2 | 1.4 | 0.3 | 0.8 | 0.8 |

Main Function of Mica

Dry ground mica powder of Huajing is competitive in price and stable in quality. The high purity mica powder produced by grinding without changing any natural property. During the whole production , we adopt total enclosed filling system to make sure the product quality; The screening process uses patent technique ensuring the stability of quality and well-distributed particle,then satisfy some customers’ higher request. As the superior characteristic, Huajing mica powder is widely used as filling material in plastic .

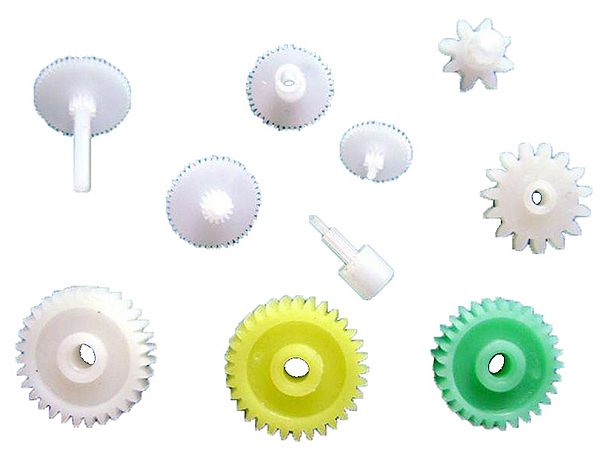

Application of Mica in PP

Mica powder has excellent electrical properties, high breakdown voltage, low dielectric constant, low loss factor and good arc resistance. At the same time, mica has low hygroscopicity and high thermal deformation temperature when mica is used as filler, which is beneficial to maintain electrical properties in humid environment and higher temperature. For example, when 50% mica is added to PP, the breakdown voltage is more than doubled. The application of mica modified PP in automobile and household appliances to produce automobile dashboard, headlight protection ring, motor fan and other parts can obviously improve its rigidity, heat resistance, dimensional stability and molding shrinkage.

Application of Mica in PP-R

PP-R pipe is a new type of PP random copolymer green building material widely used in recent years. Its temperature resistance is greater than or equal to 90 degrees, low cost and easy to use. The PP-R pipe with mica has high strength, good heat resistance, strong corrosion resistance, and the cost is greatly reduced, so it has a broader market development prospect.

Applications

Product detail pictures:

Related Product Guide:

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for High reputation Mica Flake Rock - Dry ground mica – Huajing , The product will supply to all over the world, such as: Washington, Malta, Morocco, We welcome you to visit our company & factory and our showroom displays various products that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to provide you with the best services. If you need more information, please do not hesitate to contact us via E-mail, fax or telephone.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.