Well-designed Powdered Pigments For Resin - Synthetic mica powder – Huajing

Well-designed Powdered Pigments For Resin - Synthetic mica powder – Huajing Detail:

Synthetic Mica

| Size | Color | Whiteness (L.a.b.) | Particle Size (μm) | Purity (%) | Magnetic Material (ppm) | MOisure(%) | LOI (650℃) | PH | Osbestos | Heavy Metal Component | Bulk Density (g/cm3) |

| Synthetic Mica(High Tempreture Resistant 、Heavy antisepstis、Insulation、Casting) | |||||||||||

| 200HC | white | >96 | 60 | >99.9 | <20 | <0.5 | <0.1 | 7.6 | NO | NO | 0.25 |

| 400HC | white | >96 | 45 | >99.9 | <20 | <0.5 | <0.1 | 7.6 | NO | NO | 0.22 |

| 600HC | white | >96 | 25 | >99.9 | <20 | <0.5 | <0.1 | 7.6 | NO | NO | 0.15 |

| 1250HC | white | >96 | 15 | >99.9 | <20 | <0.5 | <0.1 | 7.6 | NO | NO | 0.12 |

| 2000HC | white | >97 | 7 | >99.9 | <20 | <0.5 | <0.1 | 7.6 | NO | NO | 0.11 |

| 3000HC | white | >98 | 4 | >99.9 | <20 | <0.5 | <0.1 | 7.6 | NO | NO | 0.11 |

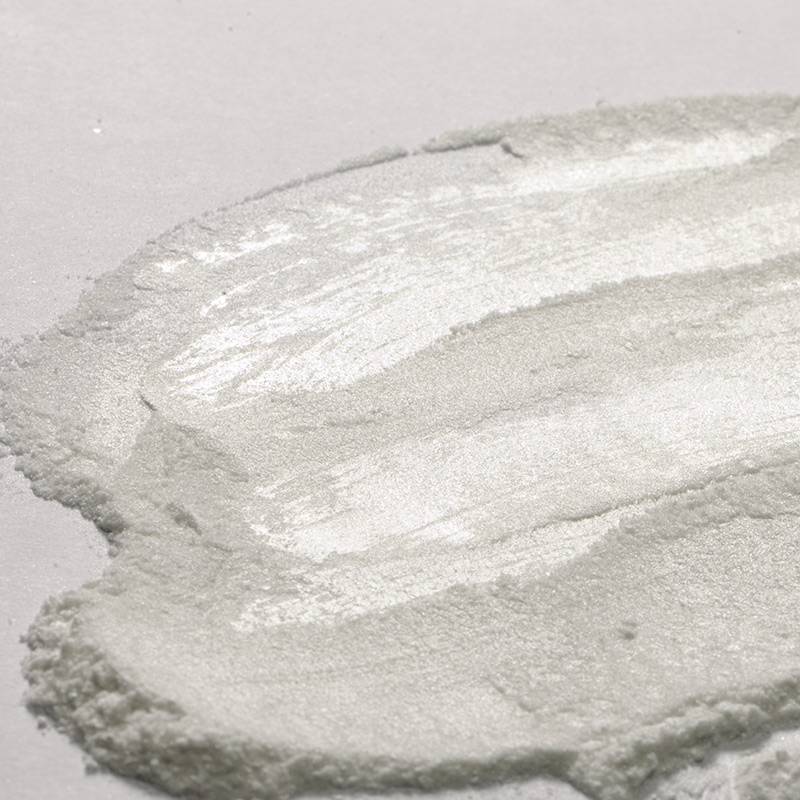

Coating Grade Synthetic Mica Powder

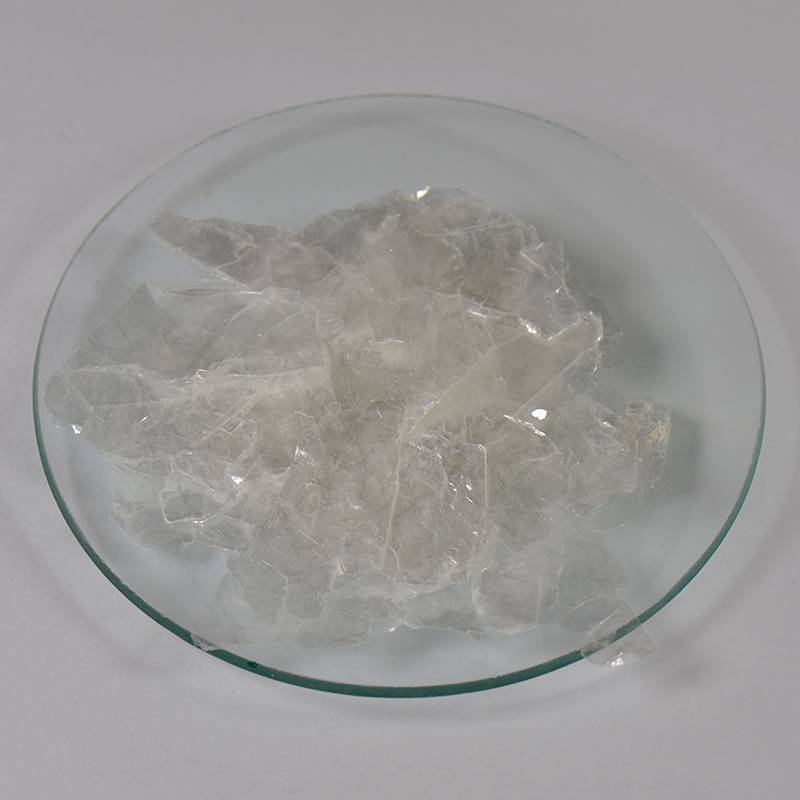

Huajing coating grade synthetic mica used hand-made synthesis flake,untrawhite and bright.It is widely applicable to high-end coating, besides the features of the natural mica powder, the heat resistance could increase to 1200℃,the purity could be 99.9%, volume resistivity is much higher than natural mica .Meanwhile synthetic mica does’t contain heavy metal ,and iron oxide content < 0.5%, thus it has excellent resistance to color change and anti-oxidation function;In addition, because of its structural characteristics, it does not contain hydroxyl (OH-), so it has a very low air volume, and great application value in the field of precision casting coatings. Such as exterior wall paint, heat resistant paint, insulation coating, corrosion resistant paint, road sign paint, waterproof paint, radiation resistant paint, spacecraft thermal control paint, etc.

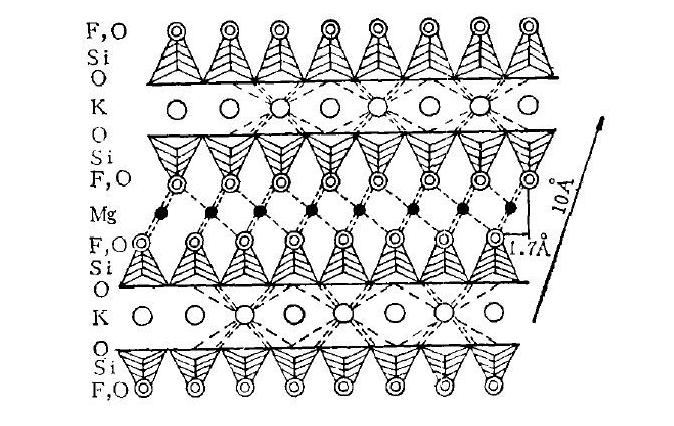

The synthetic mica belongs to monoclinic crystal system and is typical lamellar silicate. Please see the details as followings:

Here is the detailed specification about the synthetic mica powder:

1. Synthetic mica powder owns high whiteness (L.a.b. >95) and big aspect ratio,which make the coating more luster and colorful.

2. The synthetic mica heat resistance could be reach 1200℃,while the natural mica is 600-800℃, so the synthetic mica is better choice for high temperature coating.

3. Its good acid&alkal resistance make it become the best material for heavy anticorrosive coating.

4. The synthetic mica chemical stability and physical properties, it could be used into aerospace field.

5. Fine texture, large diameter to thickness ratio, strong tensile strength, radiation and uv resistance performance superior, green environmental protection

Whether tending to pollution-free, high anti-fouling architectural coatings, or to the healthy development of decorative coatings, synthetic mica powder can meet the requirements of coating manufacturers because of their own advantages, favored by manufacturers, widely used in the painting&coating industry.

Applications

Packing

A. 20 or 25kgs/ PE woven bag

B. 500 or 1000kgs/PP bag

C. as customer’s request

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Well-designed Powdered Pigments For Resin - Synthetic mica powder – Huajing , The product will supply to all over the world, such as: Montpellier, Kenya, Riyadh, Our mission is "Provide Products with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.